LoT weighing system

Category:Truck scale

Internet of Things weighing system (10-200T)

The first wave of industry represented by computers, the second wave of industries represented by the Internet and mobile communication networks have passed, and the third wave of industries is now facing the Internet of Things. Various intelligent equipment applications, character sensing, have gradually spread to all aspects of society. The Internet of Things is about to replace the Internet, and the Internet is about to disappear. It is not a trend, but a reality.

Weighing equipment is intelligent and connected to the cloud service platform to achieve remote monitoring, management, and service of the weighing equipment, providing real-time status inquiry and post-closing expert services to scale users. In this way, the customer can log in to check the working status of all weighing instruments at any time with the mobile phone. If a fault alarm is found, the customer and the weighing instrument manufacturer can be notified immediately. Weighing instrument manufacturers can also pre-judge possible problems on the spot through the failure information sent back by the instrument, and bring the parts that need to be replaced directly to the scene and remedy the disease. The efficiency will far exceed the traditional service model.

Once the Internet of Things is used on the scale, the advantages of the network can be fully utilized. When the customer has a fault request, he can directly query the nearest service outlet to arrange personnel on-site service. What's more, the Internet of Things not only brings convenience, but also prevents customers from cheating and information statistics.

● Equipment area management, authority management, verification reminder;

● Operation log record, failure statistics report;

● Weighing record report management.

How much benefit does using the Internet of Things main business bring?

● Clearly locate faults and reduce maintenance costs;

● Avoid artificial cheating and reduce business losses;

● Low-cost centralized management to achieve efficient management;

● Timely business statistics and real-time operational data;

● Hierarchical service support, fast service response

...

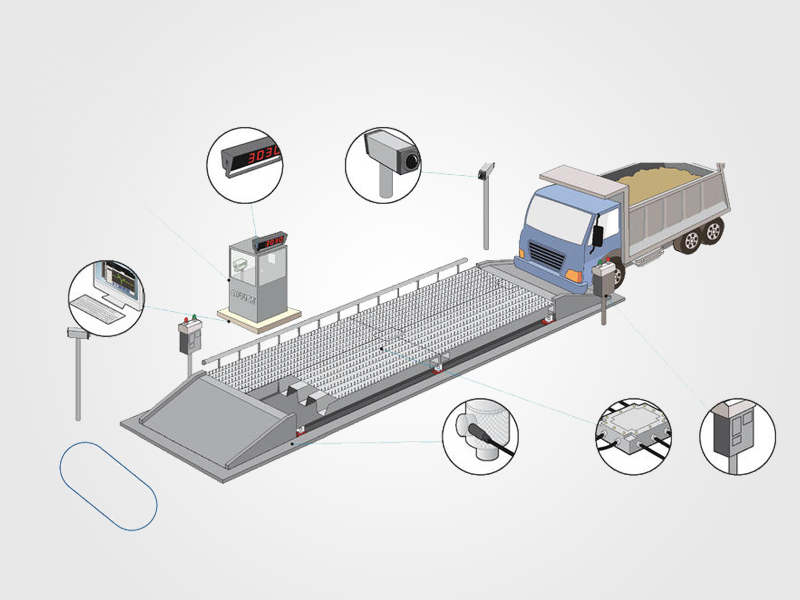

IoT weighing system architecture

Features of IoT weighing system

It is an application combining the weighing industry with the Internet, which has the following characteristics:

● The data is online in real time and can be grasped with one hand.

● Proactive notification of failures, internal insurance of mobile phone software, and double notification of SMS notification to ensure no omissions.

● The weighing data is backed up in the meter and the cloud, so it is absolutely safe.

● Remote reading and writing of parameters (according to regulations), easy to diagnose and maintain.

● Quick response, synchronization time is less than 3 seconds, real-time monitoring, and spanning geographical restrictions.

● Prevent cheating behaviors such as opening the shell, calibrating, changing sensors, etc., immediately notify the occurrence of cheating, and immediately stop the remote ability.

● Big data processing, comprehensive analysis of failures, provide basis for selection, and promote product quality improvement.

● Hierarchical user system with decentralized management authority; flexible authority configuration is convenient to meet multiple needs.

● Centralized equipment management, one user can manage multiple weighing platforms, and one weighing platform can belong to multiple users to meet the needs of multiple users monitoring the same batch of weighing platforms simultaneously.

● Complete system log function, equipment online, device offline, user login, user logout, device parameter change, device key operation execution, user assignment and modification are recorded for query.

● The equipment maintenance process is interlocked, the system updates the maintenance progress in real time, and the user can clearly understand the cause of the equipment failure and the maintenance progress.

● High-level users can post advertisements, notifications, promotions, and other information to their subordinate low-level users through pictures.

● Storage of weighing history data, equipment history faults, log records and other data for at least 5 years.

● Diversified weighing record statistical report format and multiple file output formats.

● Seamless connection with enterprise ERP system to realize data sharing.

● The important parameters of the server are automatically backed up, abnormal operation is automatically detected and the system is restored to normal operation, and the administrator is notified via SMS.

Main functions of IoT weighing system

| ● Prevent or detect weighing cheating | ● Centralized real-time management of equipment | ● Weighing and alarm message push |

| ● User Management | ● Authority management | ● Weighing report statistics |

| ● Support data transfer ERP | ● Weigh or alarm mobile phone short message push | ● Equipment repair service tracking |

Network architecture of IoT weighing system

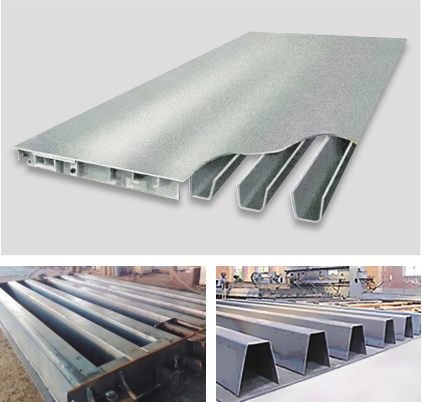

| Body structure advantage ● Introduce special equipment such as large-scale automatic welding of large robots, large-scale automatic pre-arch machines, CNC bending machines, CNC shears, and CNC laser cutting machines. Bend into a U-shaped beam. Compared with the original channel steel, it has the following characteristics: 1) The height of the main beam is 360mm, and the bending strength can be increased by 50%; 2) Continuous welding makes the inner cavity of the weighing platform completely sealed and is not easy to rust; 3) The weighing platform adopts U-shaped main beam, which effectively solves the measurement error caused by the bending of the weighing platform; 4) The U-shaped steel structure weighing platform has undergone full load loading and unloading experiments on a large-scale fatigue testing machine, and the weighing platform has no deformation; 5) The weighing platform is fastened, and the truck scale accuracy is 1/8000; 6) Adopting advanced CAD (Computer Aided Design) and CAT (Computer Aided Measurement) technology, the designed load point of the weighing platform is more reasonable. 7) U-shaped steel structure scale body is by far the most reasonable electronic truck scale body structure in China. The U-shaped steel load-bearing main beam is cut according to the length without joints, and has higher welding strength than ordinary steel main beams with joints. The U-shaped steel support platform has a distance of 1/2 smaller than that of ordinary steel, which is close to the width of automobile tires. it is good. ● The introduction of GRACC special spraying. The box type sand blasting machine is used to remove rust in the early stage of the steel plate to solve the problem of table corrosion. ● Adopt carbon dioxide protection welding to improve the welding quality of steel structures. |

| EDS load cell and signal cable 1) High precision, high reliability and good stability; 2) It adopts a bridge structure, which can be automatically reset and adjusted; it has good resistance to lateral forces and impact; 3) Easy installation and good interchangeability; 4) Double shielded wires are used to prevent animal bites and abrasion; 5) Double aviation plug-type interface, can be connected in series, without junction box, the entire scale body system protection level IP68; 6) Reliable data storage technology to ensure that module parameters are not lost; 7) Has good electromagnetic compatibility performance and strong electrostatic protection ability; 8) Bearing steel ball with rubber dust cover, can be used for a long time in harsh environments such as sand and oil; 9) Lightning and surge protection ability is strong, up to 80Ka. |

| LoT weighing display (Full touch screen) The meter uses a large-sized color LCD touch display interface with good operability. Compared with traditional meters, it has greatly improved the friendliness in weighing data display, system status display, and various set value operations. The hardware configuration and software functions related to networking are matched with the digital module with dynamic multiple data output and the mobile network communication module (WX-3) with dynamic encryption. Through the well-developed mobile network, uploading weighing records, system fault query, remote configuration parameters, communication protocols for upgrading and sensors, and communication protocols for mobile network communication modules. |

|

The main technical parameters: 1) Maximum number of verification divisions: n = 3000 2) Error distribution coefficient: pi = 0.5 3) Digital sensor interface ● Communication method: RS485 ● Signal transmission distance: in the case of 12 digital sensors, the bus can be connected to 30 meters (For longer, please contact us) ● Transmission baud rate: 9600, 19200bps ● Excitation power: DC12 ~ 14.8V ● Digital interface capability: up to 16 digital sensors ● Support communication protocols: C-type, E-type and K-type digital protocols 4) Display: 7inch 800 * 480TFT display 5) Keyboard: resistive touch screen 6) Clock: can display year, month, day, hour, minute, second, automatic leap year, leap month; 7) Large screen display interface (electrically isolated from sensor interface) |

| ● Transmission mode: current loop and RS232 ● Transmission baud rate: 600bps 8) Serial communication interface (electrically isolated from the sensor interface) ● Transmission mode: RS232 and RS485 ● Baud rate: 2400-115200bps optional 9) Ethernet interface (electrically isolated from sensor interface) supports remote communication |

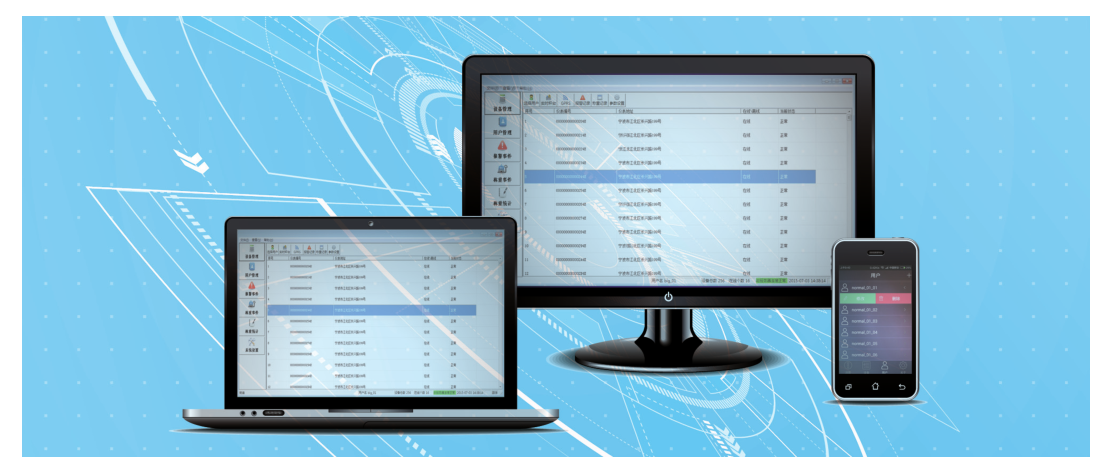

APP client introduction

● User login function: user rights control, illegal users cannot successfully log in to the system.

● Weighing equipment management function: each user can manage different number of weighing equipment according to the authority.

● Real-time data of weighing equipment: You can browse real-time data information, real-time status information, real-time weighing data, system structure, parameter information, etc. of a weighing equipment.

● Weighing equipment historical data: You can query the historical data information, alarm information, weighing data, weighing equipment log records, and parameter modification records of a weighing equipment.

● Weighing equipment real-time alarm: When a fault occurs in the weighing equipment to which the user belongs, it is immediately fed back to the user's mobile phone, and can be set to notify the user by means of system notification or prompt tone.

● Real-time weighing of weighing equipment: When a weighing record is generated in the weighing equipment to which the user belongs, it is immediately fed back to the user's mobile phone and can be set to notify the user by means of system notification or prompt tone.

● Weighing equipment parameter setting: Users can browse the relevant parameter information of the weighing equipment at any time, and can set some parameters in the weighing equipment that do not affect the measurement performance remotely.

● Advertisement for large users: Advertisements, announcements, and notifications posted by users will be displayed on mobile apps.

● Tracking service function: When the weighing equipment fails, the system will track the entire troubleshooting process, including the work progress of relevant personnel, time nodes, customer service evaluation, etc., and related information will be provided to authorized users to browse and update in real time.

PC client introduction

● Basic functions: The basic functions of the PC client include all the functions of the APP client.

● User assignment: High-level users have the rights to assign and modify low-level users. They can create new users, delete users, or modify user content.

● Advertising: Advanced users can publish advertisements, announcements, notices, etc. to a specified user group.

● Report statistics: The query results can be easily generated into a spreadsheet or other file formats.

● Information printing: You can print the query results.

● E-mail notification: Reports can be sent to specified user mailboxes on a regular basis.

● ERP system access: Real-time data, real-time status, weighing records and other data information of the weighing equipment can be connected to the user's ERP system, which is convenient for users to browse and query.