Unattended weighing system

Category:Truck scale

Unattended weighing system

With the rapid development and popularization of global information technology, information technology has rapidly penetrated into all areas of the economy and society. How to improve the management level, improve the automation management, reduce the management cost, and how to improve the market competitiveness of enterprises are important contents that enterprises must consider at present. Floor scales are the direct basis for the settlement of large quantities of materials such as raw materials and products. However, in the actual production process, materials are sometimes embezzled by relevant personnel using illegal cheating methods, and it is generally difficult to detect. How to effectively prevent cheating is putting forward higher requirements for enterprise management.

System advantages:

1. Try to avoid filling in the form manually. Achieve a high degree of automation, reduce human intervention and improve the speed of passing.

2, can automatically identify vehicle information and data comparison in the information database. Such as: the vehicle's own weight, the owner's information, the type of goods being pulled, etc .; through the optional RFID equipment, it can effectively avoid the exchange of licenses for different vehicles or repeated weighing on the same vehicle;

3. Real-time monitoring of the scale remote control system to avoid collusion between inside and outside to make counterfeit tickets and use the scale remote control to change the weighing value. To prevent the vehicle from being weighed irregularly in the process of weighing, change the weighing value (the vehicle is not standing firmly, the vehicle is not fully loaded ...); through the optional floor scale electronic dog, once suspected cheating is found (or the scale is not standardized) The system will alarm automatically.

4. All weighing data cannot be modified by non-administrators in this system, and non-administrators cannot cancel the system's anti-cheating work. The scales not only record the weighing data, but the photos captured during weighing are saved with the scales.

5. Vehicles use radio frequency cards to correlate with information such as car number, tare weight, and urban area;

6. Weighbridges are equipped with cameras, infrared vehicle positioning and other auxiliary anti-cheating devices to prevent cheating from drivers and drivers.

7. Network management and full-process supervision of information can be achieved, and leadership inquiry can be achieved through LAN + Internet.

8. The system reserves a data interface, which can send data to the company's existing ERP and other third-party systems for unified management.

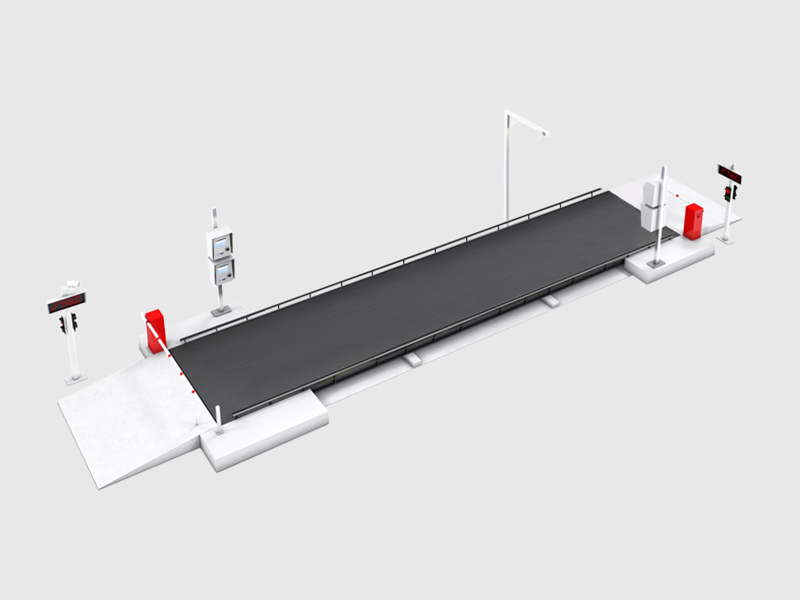

system structure:

1. Network-based structure: This system uses the internal Ethernet structure of the enterprise to connect the server, office management, and plant equipment to the network. The plant operating computer stores all the collected data in the server. The pound room and other clients do not retain any data. To ensure data security. The computers in the factory area are independent of each other and do not interfere with each other. If one place fails, other work is not affected.

2. The structure of the self-developed development platform: This system software application design is based on our company's self-developed development platform, combining multiple technologies (such as server / browser technology, automatic control technology, weighing technology, and RF RFID technology) , Video capture technology, DCS configuration technology, etc.), it can be developed and debugged on-site, which is a solid foundation for the rapid implementation of the system, and can be expanded in the fields of management and control in the future.

3. The structure of the weighing room equipment: The weighing room computer uses an industrial computer (industrial control computer) connected to the weighing controller, and then the weighing controller is connected to various on-site control and operation equipment (such as credit card terminals, LED display, alarm, Camera, etc.). For multiple pound houses, the system sets up a set of independent equipment management configuration lists for each pound house, and the network management does not affect each other.

4. System interface: This system provides a data interface, which can conveniently provide data to enterprise management software.

The main technical parameters

1. System environment

Server operating system: Windows2003Server / Win7

Client operating system: WindowsXP / Win7 / Win10

Software products

Configuration Control System: SmartFields 2.0TM

Development tools

Platform: Weighing Browser / Developer

Report Design: FastReport3

4, database management system

Server database: FireBird2.0 (open source large relational database)

5.Hardware system

Network architecture: Gigabit Ethernet

Server: PC / CPU 2G / Memory 4G / Hard disk 1T / Ethernet 1000M

Management machine: Lenovo Business Series

Weighing control cabinet: PA200

Other accessories: use brand products in the industry for matching

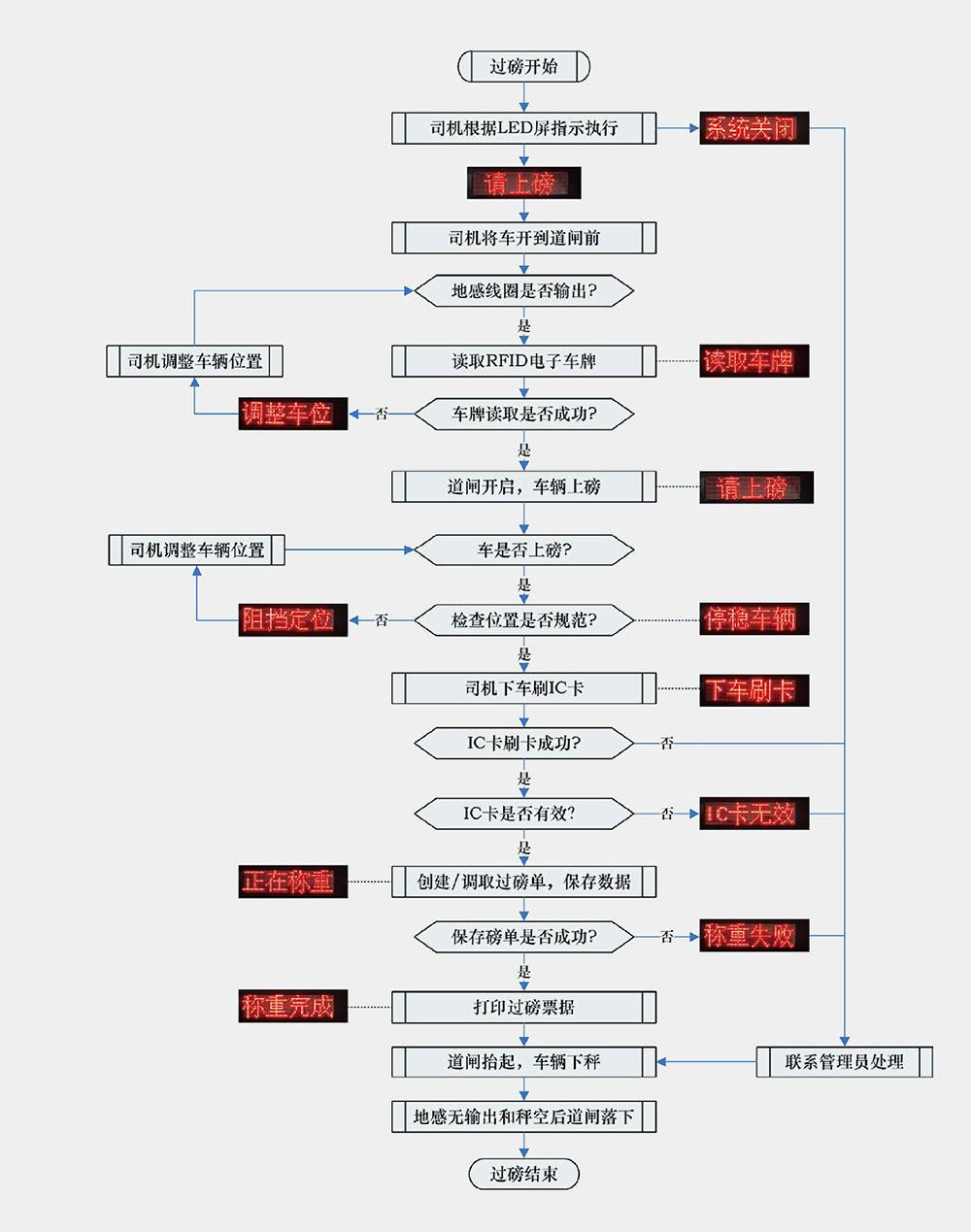

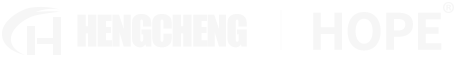

Schematic diagram of the third generation unattended weighing system

Third-generation unattended weighing system-automatic execution process